Concrete Block Machine

A concrete block machine is a machine that produces concrete blocks. these machines use electrical energy and hydraulic force to compress the mortar and shape different types of blocks.

There are a lot of different types of concrete block machines with different brands, capacities, automation levels, and working mechanisms made by different concrete block manufacturer companies. depending on your project and budget you need to consider different factors and choose the best machine for your business.

If you are looking to choose a concrete block machine and you don't know what is the best option for your plant, this article will help you with the most important factors.

1. The project land:

The first factor is whether you have land or not. Your land should be more than 1200 m² to operate a concrete block making machine. this land size is for the smallest machine that can produce 4000 pieces of standard blocks in one shift and also with an automatic system.

2. Choosing between semi-automatic and automatic:

one of the most critical factors on the price is the automation level. if your land is bigger than 2500 m² and the labor cost is cheap in your country, the best option is the semi-automatic. The customers in such countries prefer higher capacity semi-automatic machines to lower capacity automatic machines. These machines are also called brick making machine.

If your land is smaller than 2000 m² and labor cost is expensive in your country the best option is the automatic block making machine.

3. Choosing the concrete block making machine capacity:

to choose the right capacity you need to know what are the sizes of these machines. To avoid confusion I am going to explain it this way.

the size of the machine is determined by the number of standard blocks it produces in each press. Standard block means a block with the dimensions 20cm width, 40cm length, and 20cm height.

a premium quality concrete block machine produces 1000 cycles in one 8 hours shift.

in other words, a size 4 machine produces 4000 pieces of hollow blocks in 8 hours. This is the smallest machine that we have.

The other sizes of the machine are size 6, size 8, and size 10. in the product part, it will be explained more.

4. number of molds needed.

This depends on your country. Different shapes of concrete blocks are used in different countries. you need to study the market to see which products are most popular and order the molds.

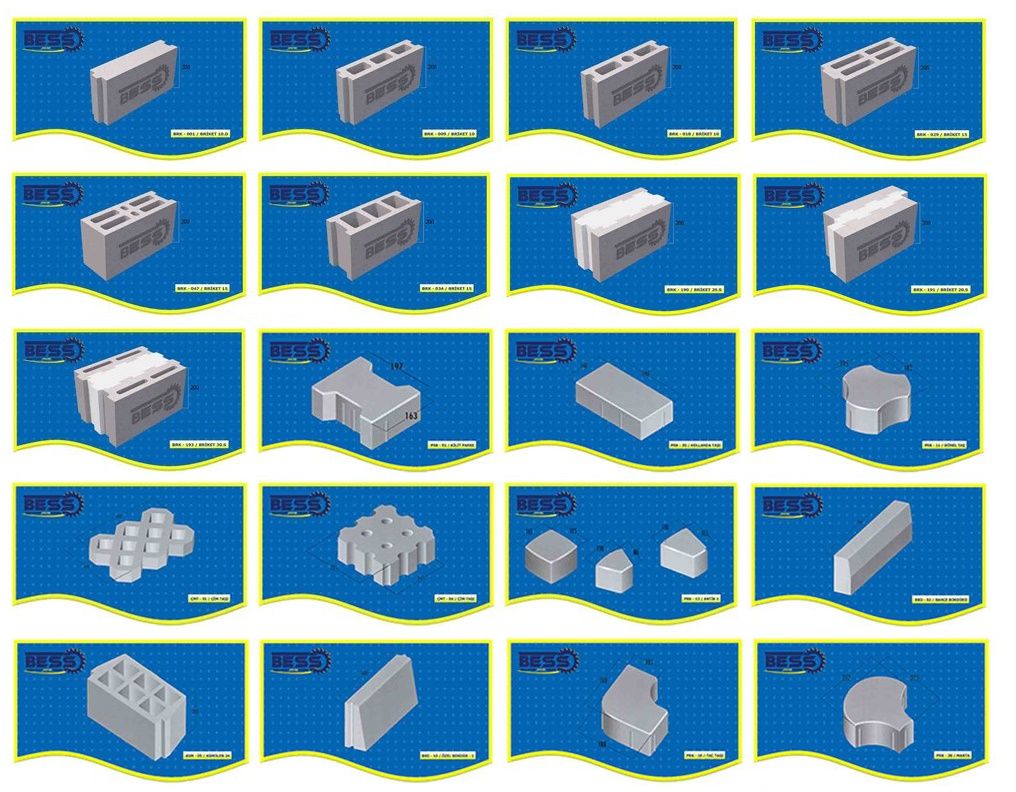

Concrete Block Machine products

concrete block machines work with molds so, by changing the molds you can produce different shapes. the height of the product should be between 5cm to 30cm.

These products are:

1. Hollow blocks

2. Solid blocks

3. paving blocks (interlocking blocks)

4. Lego blocks

5. Gutters

6. Curbstones

7. Styrofoam concrete blocks

Concrete Block Machine Manufacturer Company Bess

As a concrete block manufacturer company with more than 350 working plants in 32 countries over 15 years, Bess company's main focus is producing premium quality concrete block machines and gaining customer trust and customer satisfaction.

To reduce the fault rate to its minimum in electrical equipment and hydraulic equipment Bess uses only German brands. This means the machine will be more reliable against faults and failures.

In some African countries, there are not many engineers with enough knowledge to repair complicated machines, the best choice for such countries is the semi-automatic machines. Bess has these types of machines as well as other types.

Bess company also produces its own molds. We use CNC machines to cut the metal sheets and to produce concrete block molds. the hardening process is also done twice to have the maximum strength and longer life.

for hollow blocks we mostly use st52 or Hardoax metal sheets and for paving blocks CK45 metal sheets are used.

The production process of each mold takes almost 3 weeks. The concrete block molds are one of the most important parts and to make sure its manufactured right, maximum accuracy should be applied to the production process.

Bess is now a well-known brand in different countries in Europe, Africa, Asia, and soon it will be a well-known brand in the USA and Australia. You can contact us for further details and price list, our contact information is available at the end of this page.

Since we update and improve our designs at the end of each year, our machines are designed based on the latest technology. The maintenance of our machines are so simple and when we come to install the machine in your country, we will train your operators to know how to use the machine and how to do the maintenance.

Conclusion

There are different companies in different countries that produce these machines, the most important thing to choose the machine is to find a high-quality machine with reasonable prices. Consider that cheap machines look the same as expensive machines in the first look. but trust me there are a lot of differences between the machines when you compare them item by item. Cheaper machines may look appealing in the beginning but in long-term use, you will face a lot of problems and after a certain point you won't even be able to fix it anymore.