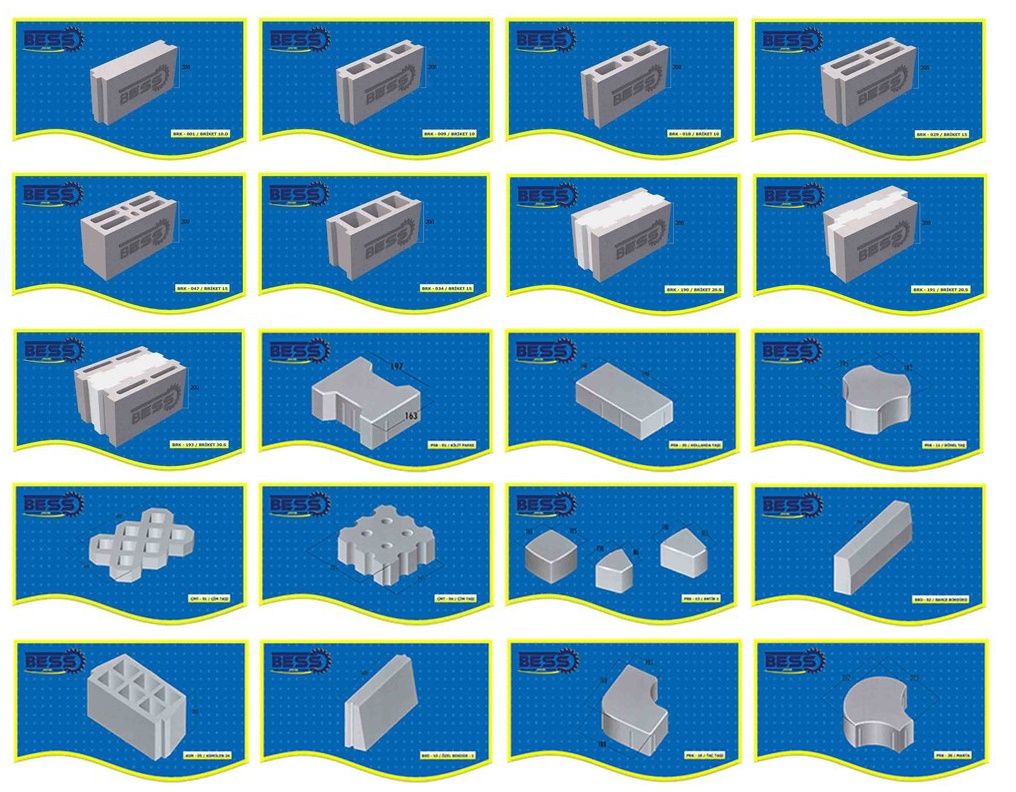

Paving block making machines are machines that produce paving blocks using compression and vibration. Consider that the same machine can also produce hollow blocks, solid blocks, curbstones, gutters, and any shape with a height between 5cm to 30cm. All you need to do is to change the concrete block mold.

To produce different shapes you need to change the mold. The process of changing a mold takes around half an hour. Since Bess paving block making machines are designed based on the latest technology using European standards, the mold changing process is an easy process.

To use the paving block machine you need an aggregate hopper to restore your raw material in it and also you need a mixer to mix the raw materials with cement and water to have a mortar.

After the mortar is shaped it is delivered to the mortar hopper of the machine. The machine uses this mortar to shape the paving blocks with the help of the concrete block molds. To see what type of products the paving block making machine can produce you can visit our mold gallery.

Technically the paving block making machine has 2 hoppers, one hopper is for thick material which is replaced at the button of the paving block, and in the second hopper, the mortar with finer materials is used to have a better and smoother surface. You can also add color pigment to the surface material to have different color materials.

You can also use a single hopper machine to produce paving blocks, the only difference will be that the produced paving blocks will be with one layer instead of two layers. The single hopper machines are called hollow block machines because they are mostly used to produce hollow blocks.

Paving Block Making Machine Capacity

The capacity of the machines in this industry is determined by the number of standard hollow blocks (20cm width x 40cm length x 20cm height) that the machine can produce in one press.

The smallest paving block making machine that we have can produce 4 pieces in one press and 4000 pieces in 8 hours. It's called the PRS402 paving block machine.

The table below shows different capacity machines that we have:

| Machine Name | Automation Level | Hollow Blocks In One Press | Paving Blocks In One Press | Total Capacity |

| PRS402 | Semi-Automatic | 4 Pieces | 12 Pieces | 300 m² |

| PRS602 | Semi-Automatic | 6 Pieces | 16 Pieces | 400 m² |

| PRS802 | Semi-Automatic | 8 Pieces | 20 Pieces | 550 m² |

| PRS1002 | Semi-Automatic | 10 Pieces | 25 Pieces | 700 m² |

Paving Block Making Machine In Your Country

Bess company started its international machine manufacturing business in 2005 and thanks to its premium quality machines and reasonable prices, also efficient aftersales system, it started to grow rapidly and now we have more than 350 working machines in 32 different countries. to see if we have a paving block making machine in your country, you can contact us directly.

our brand is famous in the construction industry in many different countries. Now we are expanding our business in European countries as well as Arabic countries and African countries. the reason for this variety is that we have machines suitable for every budget.

PRS602 automatic in different countries:

PRS602 semi-automatic in different countries:

PRS400 semi-automatic system in Somalia:

PRS600 semi-automatic in Georgia:

Paving Block Making Machine Price

The paving block making machine price depends on different factors. To have a general view I will discuss them one by one.

1. The capacity of the paver block machine: the bigger the capacity of the paver block machine is the more expensive it will be. Because the size of the machine and hydraulic unit and electric unit needs to be bigger to handle the higher capacities. having the right paving block making machine in your country is the most important decision and choosing the right capacity is one of the most important factors.

2. The automation level of the machine: apart from the capacity one of the most critical factors on the price is the automation level. To prevent future errors we only use German brand electrical units for our electrical panels. European brands are a little bit expensive so the automatic machines will be more expensive.

3. Number of concrete block molds you choose to have with the machine: Since we use ST52 and CK45 for our molds, the quality of the molds is high. We give an 80.000 press guarantee with our molds. The concrete block mold price depends on the paving block making machine capacity.

Below is the video for one of our paving block making machines installed. you can find more videos in BESS Machine EN.

Technical advice that the paver block machine manufacturers try to keep as a secret:

If you are living in a developing country where labor costs and land are cheap you better buy a semi-automatic machine with a higher capacity. This will be more beneficial for you. You need around 6 workers for your plant and a minimum of 2000 square meters of land to run your semi-automatic plant.

For more details, you can check brick making machine as well.

The countries in which semi-automatic machines are popular: Ghana, Gabon, Somalia, Djibouti, South Africa, Mali, Ivory Coast, Lebanon, Hungary, Nigeria, Somaliland, and Kosovo.

IF you are living in a developed country with high labor costs and expensive lands you better choose an automatic paving block making machine. This is a good way to reduce the number of workers and also reduce the land size. You will need around 4 workers for your plant and around 1000 square meters of land for the automatic concrete block plant.

The countries in which automatic machines are popular: Norway, Netherlands, Spain, Australia, New Zealand, Canada, USA, Serbia, and Italy.

For further details or a quotation, you can contact our English department anytime.